The LABORATORY OF ANALYSIS OF MATERIALS AND CONSTRUCTIONS has as its main object education and research in the fields of materials, as well as the design, analysis and experimental investigation of constructions from conventional and advanced materials, such as composite materials.

Educationally, it serves the needs of all courses (theoretical and laboratory) in the field of materials and construction engineering of the Department of Mechanical Engineering.

It provides specialized services for the technological certification of materials, products and constructions, as well as solving technological problems related to the development of new materials and constructions. Special experience has been accumulated in the simulation of thermal and mechanical behavior of materials, constructions and processes using computational engineering methods of boundary and finite elements, as well as the application of various types of sensors in materials and constructions, in order to measure mechanical and thermal quantities.

Research areas

Materials: Composite materials, Metallic materials, Development of advanced materials, Experimental characterization of materials, Special experimental applications on structures, 3d printing

Simulations: Finite element and boundary element methods, Simulation of transport phenomena, Mechanical Simulation of materials and structures, Thermal Simulation of materials and structures, Multiscale simulation of materials, Simulation of dynamic phenomena

Equipment/infrastructure

The laboratory occupies an area of 200 m2 and meets all hygiene and safety rules. It has recently been completely renovated and all its spaces are air-conditioned.

General testing machine: INSTRON 8802 servo-hydraulic with 250kN capacity and two-axis optical elongation measurement system.

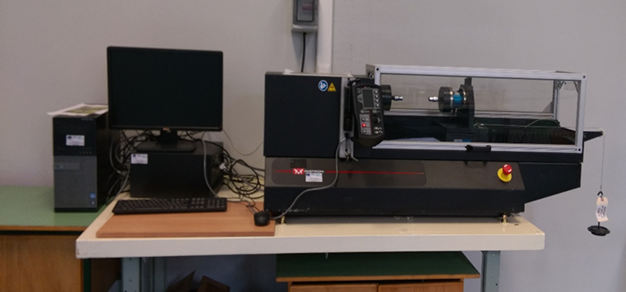

Torsion machine: INSTRON MT2 electric torsion machine with a maximum capacity of 120 Nm. torque cells of 2.25 Nm and 120 Nm are available.

Multi-channel measurement recording system: With the possibility of adding additional recording cards. Maximum number of channels 40.

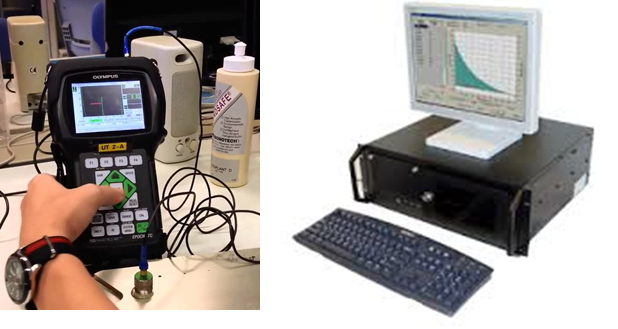

Non-destructive testing equipment:

• Epoch LTC flaw detector.

• Caliper 45MG, Olympus.

• Mistras PAC PCI-2 4-channel acoustic broadcast system.

• Nortec 500S Eddy Current Non-Destructive Testing System.

Scanning Electron Microscopy Unit of the Faculty of Engineering, University of Peloponnese: The ESA has access to the SEM of the Faculty of Engineering. Field Emission Scanning Electron Microscopy (FE−SEM, FEI InspectTM F50).

Computer system: 8 server scalable array computer system. Server HP ProLiant SL2500 Intel Xeon.

Computational packages: Finite element packages ANSYS, HyperWorks. Border Pack.